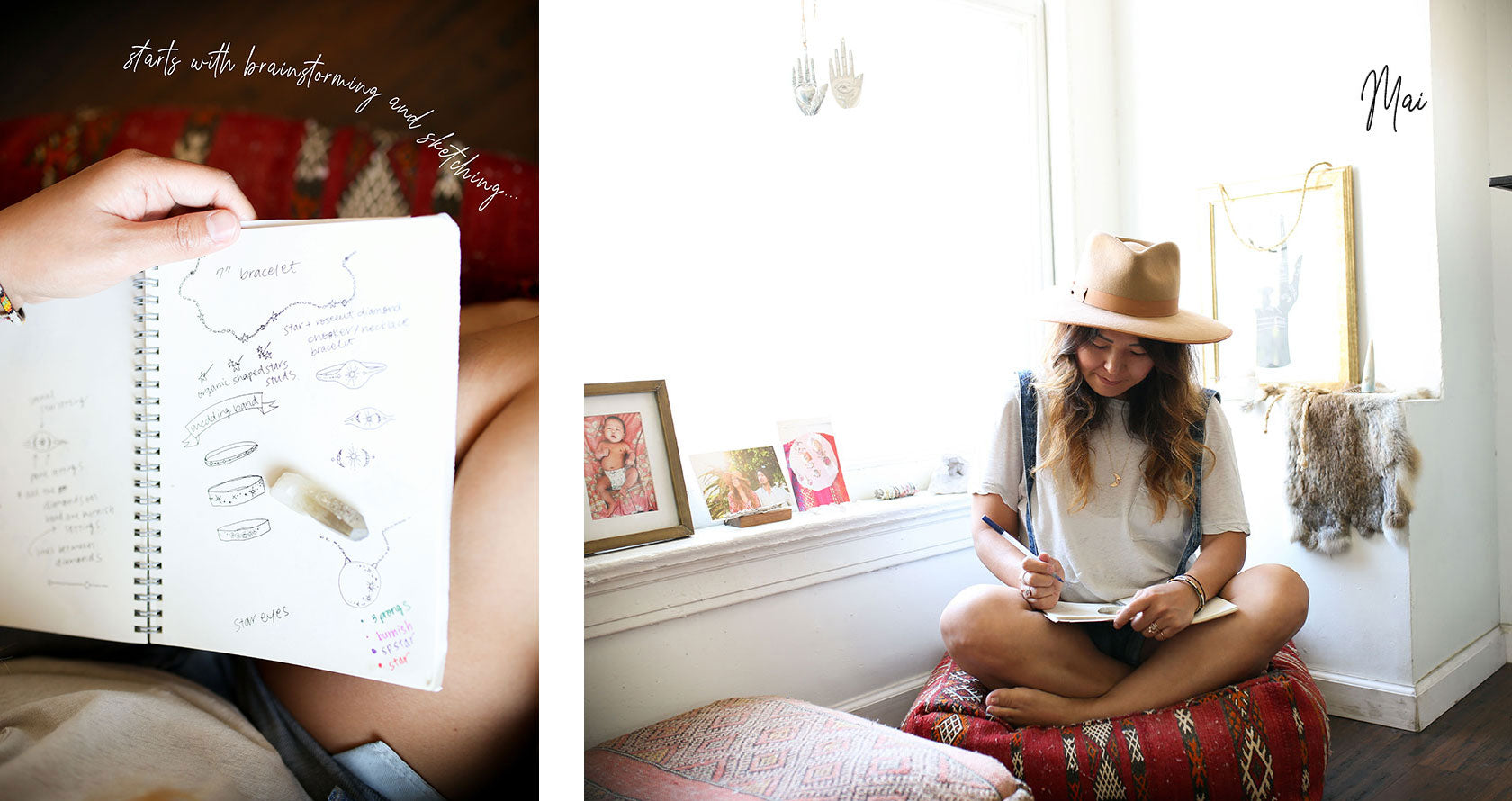

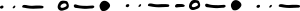

How Sirciam is Made

Idea’s become more than they are

Wax Carving

Creativity

Mai puts her heart out here and begins to carve, file, melt, burr and shape a block of wax, bringing her ideas to life right before our eyes.

Sometimes it takes many hours of adjusting and readjusting but other times it just takes form quite quickly.

Once nearly complete, Chris takes a look at the final wax and makes technical adjustments where needed and then the original artwork is brought to a casting house

This is where we hold our breath hoping that its safely returned to us in its alloyed form. We choose silver as it’s easy to work with and to simply keep in a box on a rainy day won’t break the bank.

During this stage it’s incredibly important that all things technical are addressed here while keeping all the proportions and inherent details. Every one of our pieces follow a certain form and structure, just like in nature where everything appears random but there is a universal sense to it all. From reshaping and resurfacing through laser welding, to diamond and stone spacing calculations through markings, all must take place during this stage. It is through a perfect master an acceptable piece will emerge while maintaining our artistic integrity.

Center Stones and Lapidary

Bringing Out All the Colors

The special colors and shapes of our stones are based on naturally occurring pieces in our gemstone collection.

We try to reproduce these shapes from our gemstone stock of rough tourmaline, slices of the rough stone, and sometimes even recutting finished rose cuts. Although nature creates these stones and are all beautiful in their own right, we are a little particular about what parts compose the final center stone.

We always try to yield the cleanest stone with a light amount of inclusions adding character and an artistic element.

Magic happens here as we shape away and bring to life what we see in our minds eye creating shapes, colors, and textures not typically used in fine jewelry.

Polishing & Finishing

Make It Shine Like the Stars

Cleaning and preparing the first gold casting from the mold seems like an easy task but is an art in itself.

Firstly, we need to check the casting to see if it’s worthy of our love, time and attention. The casting needs to be inspected for porosities or any structural problems prior to moving forward.

The excess material, double lines from the mold, and porosities in the gold all need to be addressed in a specific sequence.

We refine the process and techniques we use for each piece as they all have different requirements. Once prepolished, the shine will tell us how well everything came together.

Diamond Setting

Never Sleeps!

The third phase of magic happens here when our diamond setter puts his time and experience to work.

Hand set with a microscope using old world techniques, he bur’s, drills, beads, hammers, and etches our delicate stars and extravagant bright cuts with a carbide tool.

It has been said that every hand has a special touch, and this individual knows all of our Sirciam pieces

always exacting his best.

Polishing & Finishing

Yay, Finally the Beautiful Piece of Jewelry is Done!

The final polishing or satin of our piece needs to be merely a touch up, delicately but all encompassing. The beauty will be brought out best here depending on how the diamond setter worked as well as the previous steps.

Luckily, our diamond setter only touches the places he sets, leaving this last step to be very easy. If the diamond setter is sloppy, and the ring is scratched or touched unnecessarily, the polisher has no choice but to redo all the areas as well as where the diamonds are set. Harsher compounds will eat away gold, causing metal fatigue and a higher chance for diamonds to fall out.

Final Words